Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

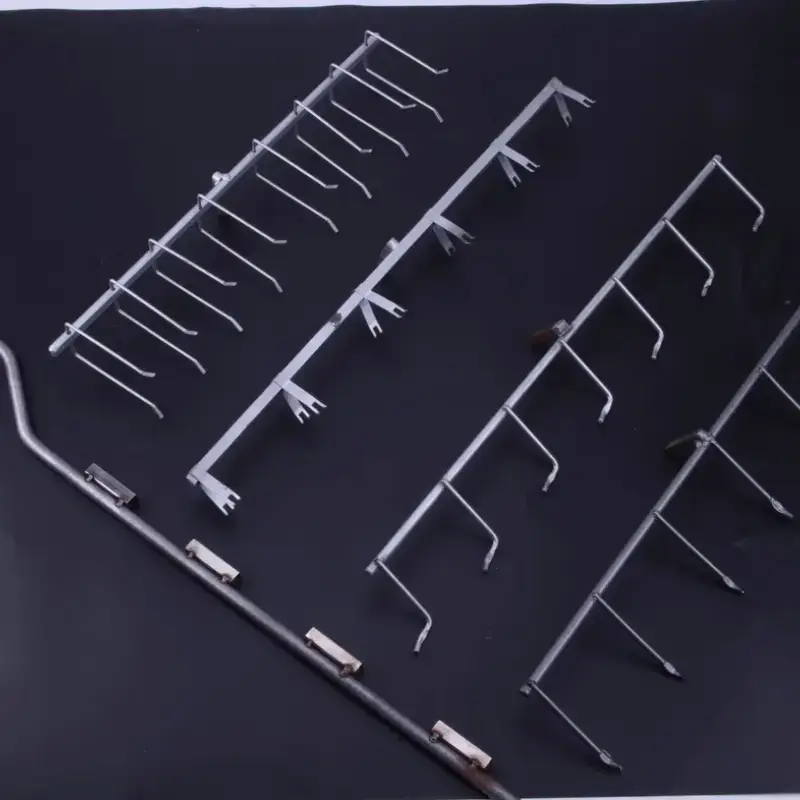

Maximize Flexibility and Coating Quality with Portable Painting Hangers

In the world of industrial coating, efficiency, consistency, and adaptability are essential—whether you're working with small batches or high-volume orders. Portable painting hangers offer a versatile and robust solution for optimizing your powder coating or wet spray processes. These innovative fixtures are designed to securely hold workpieces of various shapes and sizes, ensuring even coating coverage, reducing waste, and improving overall productivity.

What Are Portable Painting Hangers?

Portable painting hangers are modular, reusable fixtures constructed from high-strength materials such as carbon or stainless steel. They provide a stable and electrically grounded framework for holding single or multiple parts during coating applications. Their customizable design allows integration into manual and automated production environments—from batch ovens and conveyor lines to robotic spraying systems.

Whether used for metal furniture, automotive parts, architectural components, or electronic enclosures, these hangers enhance process flexibility and finish quality.

Key Features of Portable Painting Hangers

l Durable Steel Construction

Made from high-strength carbon or stainless steel, these hangers offer exceptional load-bearing capacity for light to heavy workpieces. Welded or bolted connections ensure long-term structural integrity.

l Customizable Layout

Their modular design allows for adjustable arms, hooks, or trays. Each hanger can be configured to hold one or multiple parts and may include optional rotation or tilting mechanisms to simplify spraying and ensure complete coverage.

l Excellent Electrical Grounding

Proper grounding is essential for effective electrostatic powder adhesion. These hangers enhance powder attraction, reduce overspray, and promote uniform coating thickness.

l Compatibility with Manual and Automated Lines

From conveyor systems and batch ovens to robotic spray setups, portable painting hangers integrate seamlessly into various production environments. They can be equipped with sturdy bases or mobility options (casters, rails, etc.) for easy handling.

Benefits of Using Portable Painting Hangers

Increase Production Efficiency: Hang multiple parts simultaneously to maximize throughput.

Improve Coating Uniformity: Reduce defects and rework with optimized powder distribution.

Enhance Electrostatic Performance: Achieve better powder attraction and transfer efficiency.

Support Customization: Adapt to various product shapes and sizes with standard or custom designs.

Ensure Long Service Life: Corrosion-resistant finishes and robust materials extend usability.

Applications

Portable painting hangers are widely used across industries such as:

Metal furniture manufacturing

Automotive component coating

Building materials (doors, windows, panels)

Home appliance and electronics housing

General industrial metal parts

Conclusion: Elevate Your Coating Process

Portable painting hangers are more than just supportive tools—they are essential for manufacturers seeking to enhance coating quality, operational flexibility, and cost-efficiency. By investing in well-designed hangers, you can reduce waste, improve finish consistency, and seamlessly adapt to changing production demands.

Ideal for both large factories and specialized workshops, these hangers help bring precision and reliability to your coating operations.

Want to learn how our portable painting hangers can optimize your coating line? Contact us today to explore custom solutions!